The Customer

Leading automotive manufacturing players in the industry

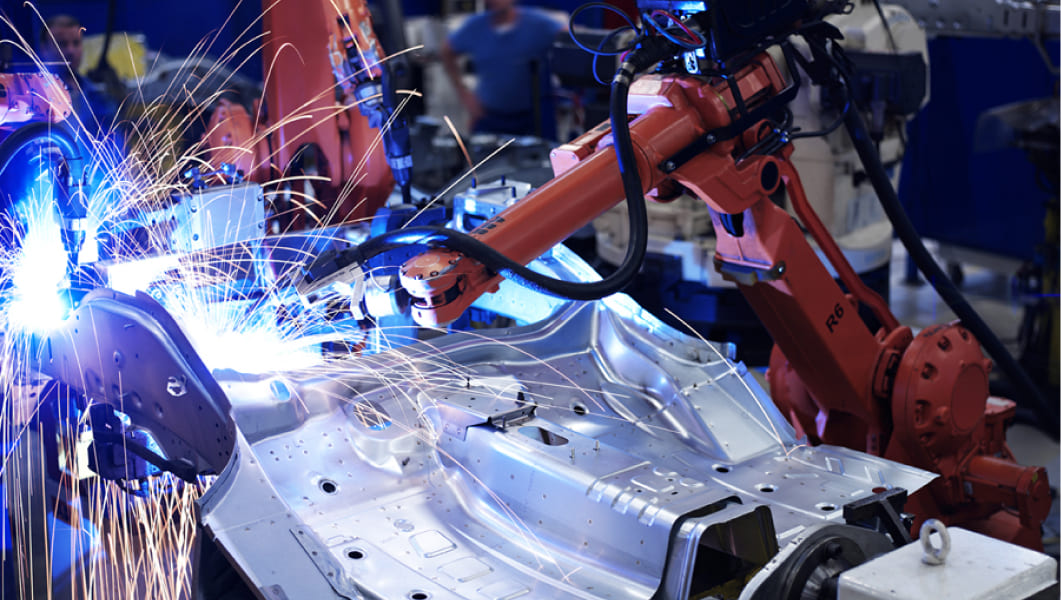

The customer is one of the leading automotive manufacturing players in the industry. With manufacturing units spread across the globe, it was a great experience for team Torque to work with them and delight them with great customer experience.

The Problem

The customer had to remove spacers from the running line due to payload issues

Due to the abrupt surge in production demands, the customer encountered significant challenges in meeting their targets. Currently capable of producing 150 parts per shift, they now require 170 parts without the addition of any new equipment. Reducing the cycle time in the existing line is always a challenging task, especially when the line builders have already completed their work. Torque as a team took on the challenge with dedication and enthusiasm, and began working on it diligently.

Approach Taken

To eliminate the robot from the existing line without impacting production

To enhance production on the existing line, we conducted an onsite assessment and analyzed potential improvements such as spot shuffling, path optimization, signal advancement, and clamping sequence adjustments. Subsequently, we presented our findings to the customer, obtained approval for the proposed actions, and successfully implemented the necessary changes.

Results Achieved

The work has been completed within the required cycle time

The project was successfully implemented and the proved out as per required cycle time and continuously line is running smoothly due to these activity number of production has increased. The customer required 170 parts in one shift but after completing the work we are making 180 parts in one shift.