Activity and responsibility

Leading automotive manufacturing players in the industry

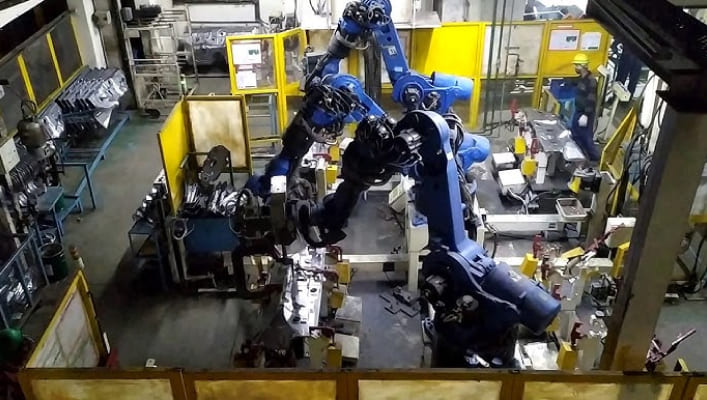

The customer is one of the leading automotive manufacturing players in the industry. With manufacturing units spread across the globe, it was a great experience for team Torque to work with them and delight them with great customer experience

The Problem

Removing a robot from the exiting line

Removing a robot from the exiting line without affecting production quantities is a highly challenging task. Initially, there were six robots on the line, but the customer requirement the removal of one robot without any impact on production. Torque as a team took on the challenge with dedication and enthusiasm, and began working on it diligently.

Approach Taken

To eliminate the robot from the existing line without impacting production

To eliminate the robot from the existing line without impacting production, we visited the site and explored our alternatives. Subsequently, we reorganized production by relocating the robot’s work area, such as the jig it operated on, to other stations. We did the proper studies on spot shuffling and sequencing for maintaining the existing cycle time. This involved adjusting the wiring of the jig, reprogramming the PLC, and shifting spot locations.

Results Achieved

The work has been completed within the required cycle time

The project has been successfully executed, and the work has been completed within the required cycle time, with the production line running smoothly without any impact on the production numbers.